Understanding the Distinction Between Single and Double Compression Cable Glands

- Blog

- Single and Double Compression Cable Glands

- October 24 2024 by Admin

- Single and Double Compression Cable Glands

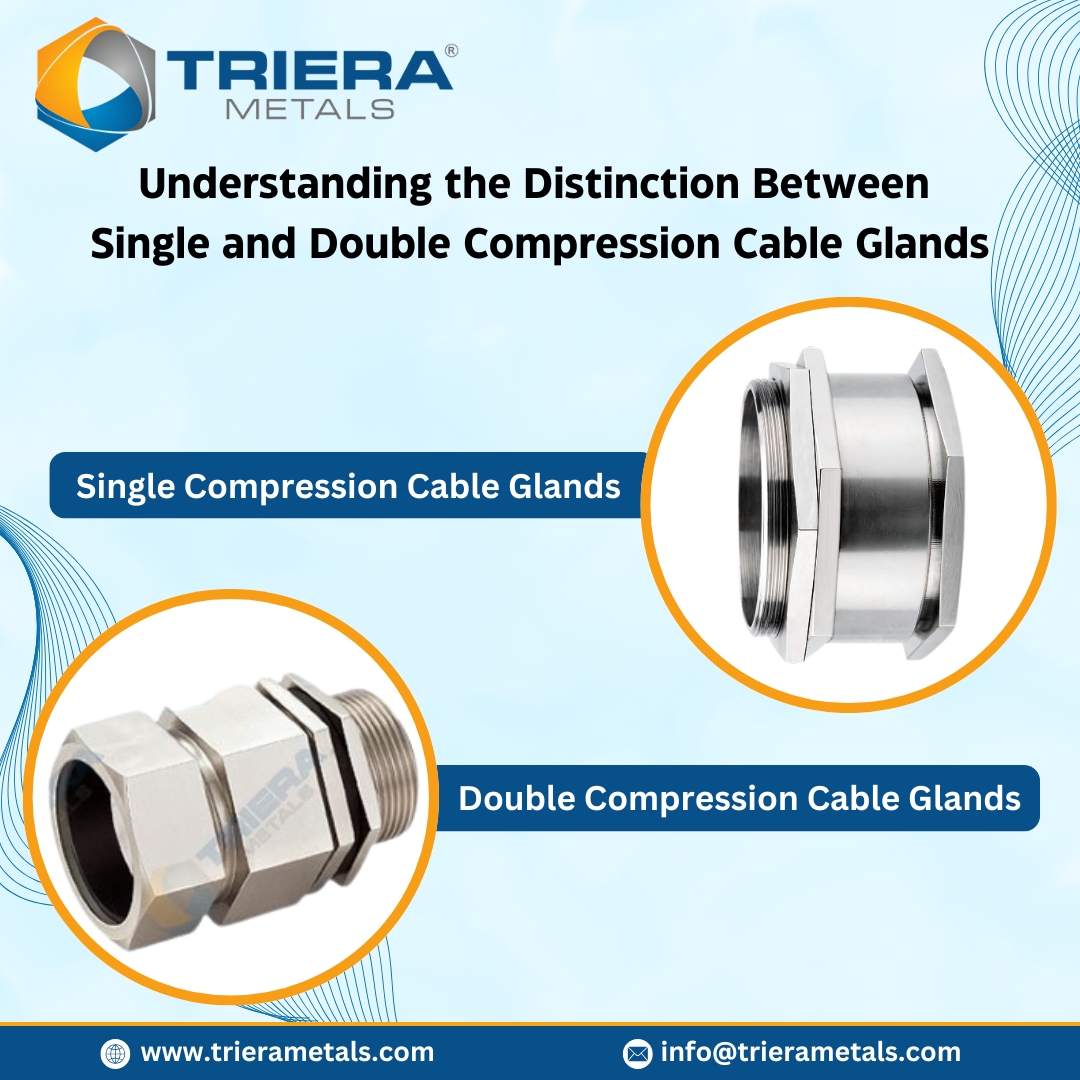

Understanding the Distinction Between Single and Double Compression Cable Glands

What Are Cable Glands?

Cable glands are mechanical devices designed to secure the end of a cable to the equipment, ensuring proper sealing and strain relief. They provide protection from dust, moisture, and environmental hazards, extending the lifespan of the cables and the systems they connect to. Cable glands are widely used in industrial, commercial, and hazardous environments.

Single Compression Cable Glands

Single compression cable glands are widely used for standard industrial applications. These glands secure the cable at one compression point—typically at the outer sheath. They offer basic sealing and strain relief, making them suitable for less demanding environments.

Key Features:

Single-point sealing: Compression occurs only at the cable's outer sheath, providing basic protection.Cost-effective: Single compression glands are generally more affordable and easy to install.

Simple construction: These glands have fewer parts, which makes them lightweight and ideal for general-purpose use.

Sealing: Typically suited for dry or low-moisture environments, where exposure to dust and liquids is minimal.

Applications:

- - Indoor electrical installations

- - General-purpose industrial machinery

- - Non-hazardous areas where dust and moisture protection are not critical

- - Environments where cables are not subject to extreme mechanical stress

Double Compression Cable Glands

Double compression cable glands provide an extra layer of protection, making them ideal for more demanding applications. These glands secure the cable at two points: the outer sheath and the inner bedding. This dual sealing mechanism offers enhanced protection against dust, water, and other environmental hazards, ensuring a higher degree of safety and durability.

Key Features:

- Dual-point sealing: Compression occurs both at the outer sheath and the inner cable bedding, providing superior sealing and strain relief.

- Enhanced protection: Ideal for use in hazardous, outdoor, or high-vibration environments.

- Suitable for armoured cables: Double compression glands are designed to handle armoured cables, offering better mechanical stability.

- IP ratings: Often rated for higher levels of ingress protection (IP), ensuring resistance to water, dust, and chemicals.

- Fire-resistant options: Available in materials and designs that resist fire and corrosion.

Applications:

- - Hazardous areas such as oil & gas, petrochemical, and mining industries

- - Outdoor installations exposed to extreme weather conditions

- - Areas prone to mechanical strain or vibration

- - High-moisture or water-prone environments like marine and offshore platforms

| Feature | Single Compression | Double Compression |

|---|---|---|

| Sealing Mechanism | Single-point compression (outer sheath) | Dual-point compression (outer sheath & inner bedding) |

| Protection Level | Basic protection, suitable for non-hazardous environments | Enhanced protection, ideal for hazardous or outdoor environments |

| Cable Types | Suitable for unarmoured or simple cables | Designed for armoured cables |

| Cost | More affordable, lower cost | Higher cost due to additional features |

| Applications | Indoor, low-moisture environments | Hazardous areas, outdoor installations, high-vibration areas |

| Ingress Protection | Standard IP ratings | Higher IP ratings for dust, water, and chemicals |

Understanding the differences between single and double compression cable glands can significantly impact the performance and safety of your electrical installations. Single compression glands are ideal for general-purpose, non-hazardous applications, while double compression glands offer superior protection in more challenging environments. By choosing the right type of cable gland for your needs, you ensure a safer, more reliable connection that extends the lifespan of your cables and equipment.